Engineering

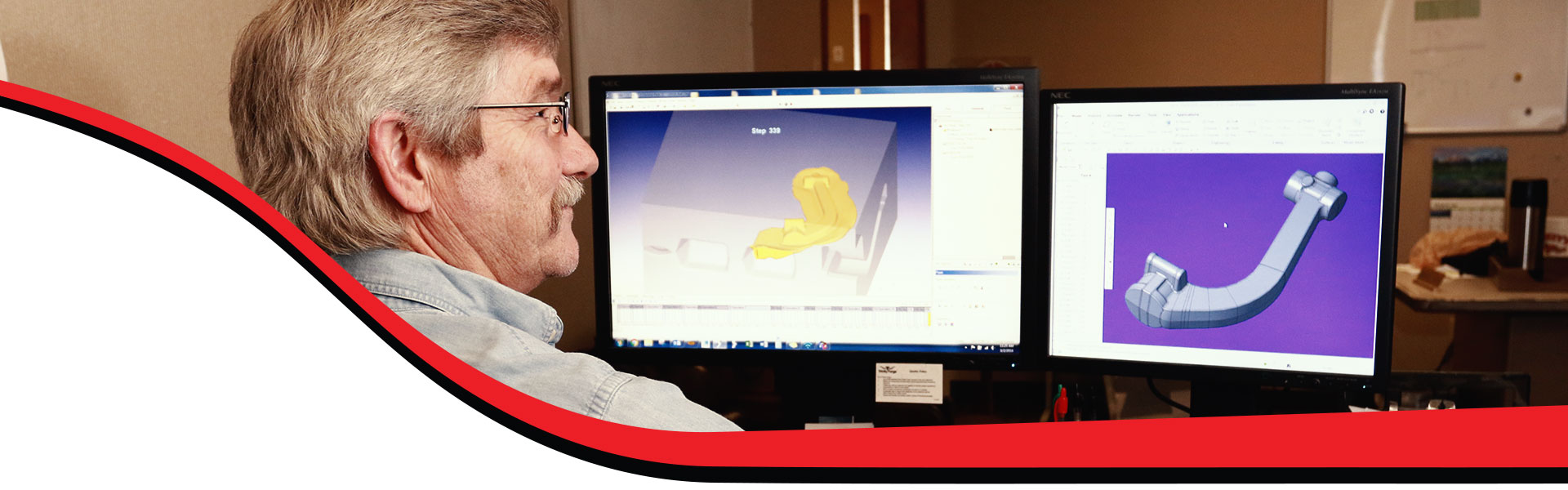

Trinity Forge's experienced engineering staff is proficient with 3D CAD/CAM systems and DEFORM simulation software. With the help of these programs, our engineering team develops forging tooling designs and reviews customer part designs for manufacturability. Careful die-design results in our ability to offer near-net forgings. In other words, parts that are close to the final shape and dimensions of the finished part in the as-forged condition. Designing parts to be near-net forgings significantly reduces subsequent machining times and material costs, while also ensuring compliance with specifications and design guidelines.

Our customers also benefit from leveraging Trinity Forge's skilled engineering team to assist with design-to-cost or design-to-manufacturability exercises. We are available to review either design concepts/prototypes or current production parts. We can suggest design enhancements for metal components that are currently castings, machined from bar or plate stock or even forged with excessive material envelopes.